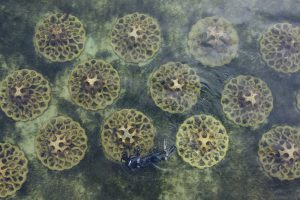

SVC is a long-standing supplier of durable civil products and customised infrastructure solutions to support the needs of local government in Victoria and beyond. With a strong focus on quality, longevity and sustainability, SVC’s product solutions for council drainage, passive irrigation and traffic management are designed to enhance urban environments and support efficient public infrastructure.

Ranging from high-strength concrete pits and drainage components to functional urban design elements and hostile vehicle mitigation solutions, our extensive product range supports the delivery of safer, more resilient public spaces. We work closely with councils, engineers and landscape architects to tailor outcomes specific to local site requirements and constraints, creating purpose-built products that are fit for application.

Our commitment to innovation and collaboration, backed by decades of industry expertise, makes SVC a respected and trusted partner to local government, helping to build safer, greener cities.