Labour savings from passive irrigation:

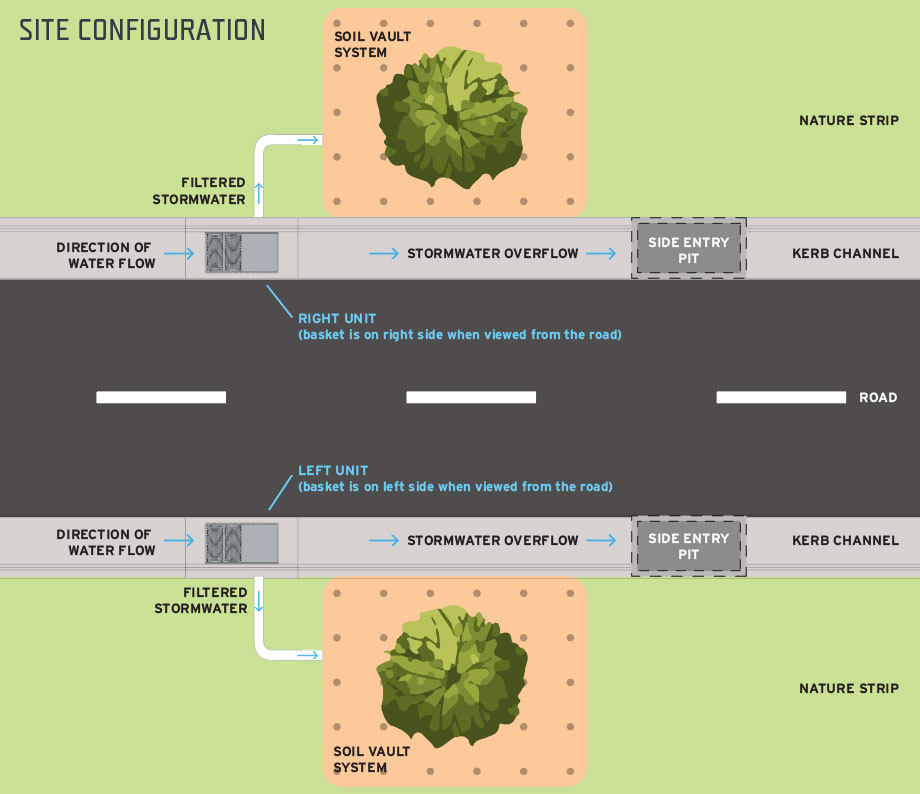

The system collects and redirects road-level stormwater directly to tree root zones, reducing reliance on frequent manual watering regimes.

Integrated filtration system:

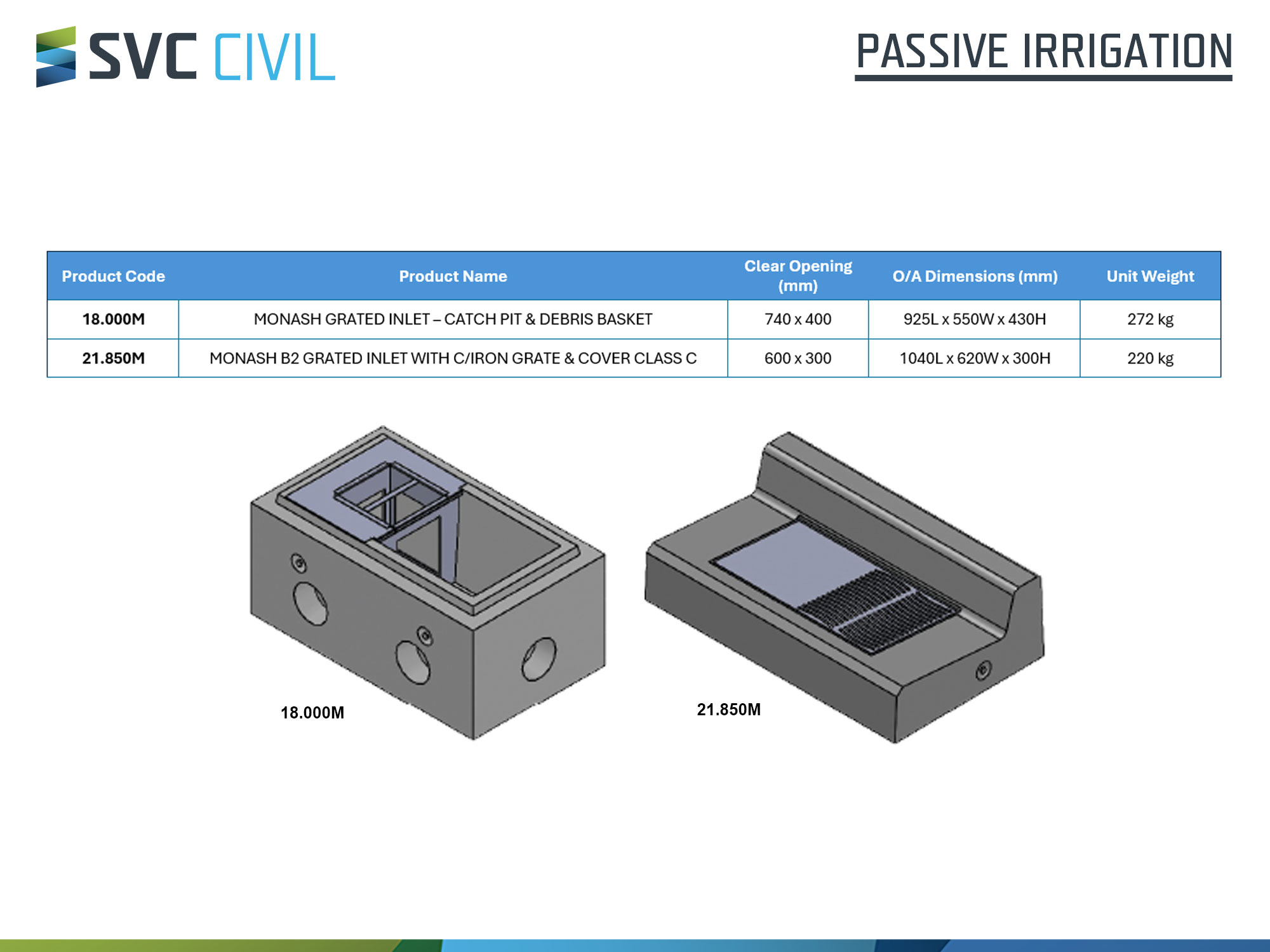

A dual-stage steel silt basket captures litter, debris and fine sediment, helping prevent blockages and protecting downstream soil vault systems.

Low maintenance design:

Requires only a 3–6 month maintenance cycle, subject to site conditions, delivering significant time and labour savings for council maintenance crews.

Fully contained precast unit:

Supplied as a single, integrated system with pre-assembled internal components, simplifying installation and reducing on-site construction time.

Pedestrian-safe configuration:

Features a Class C pedestrian-safe grate, making it suitable for footpath, nature strip and roadside environments.

Kerb-integrated solution:

Designed to match a B2 kerb profile for installation directly within the kerb channel, providing a discreet, robust and functional streetscape outcome.

Overflow protection:

Installed upstream of a side entry pit to ensure excess stormwater is safely captured by the existing municipal drainage network during high rainfall events.

Sustainable and durable:

Manufactured using SVC Eco concrete containing recycled waste and reduced embodied carbon, supporting council sustainability targets while delivering long-term asset performance.