SVC’s On-Road Speed Humps are a durable precast solution for managing vehicle speeds in car parks, commercial accessways and local streets.

They are designed to solve the critical safety issues that occur when vehicles travel at high speeds in areas conducive to high pedestrian activity. Speed humps provide an effective on-road speed deterrent that successfully encourages drivers to reduce speed.

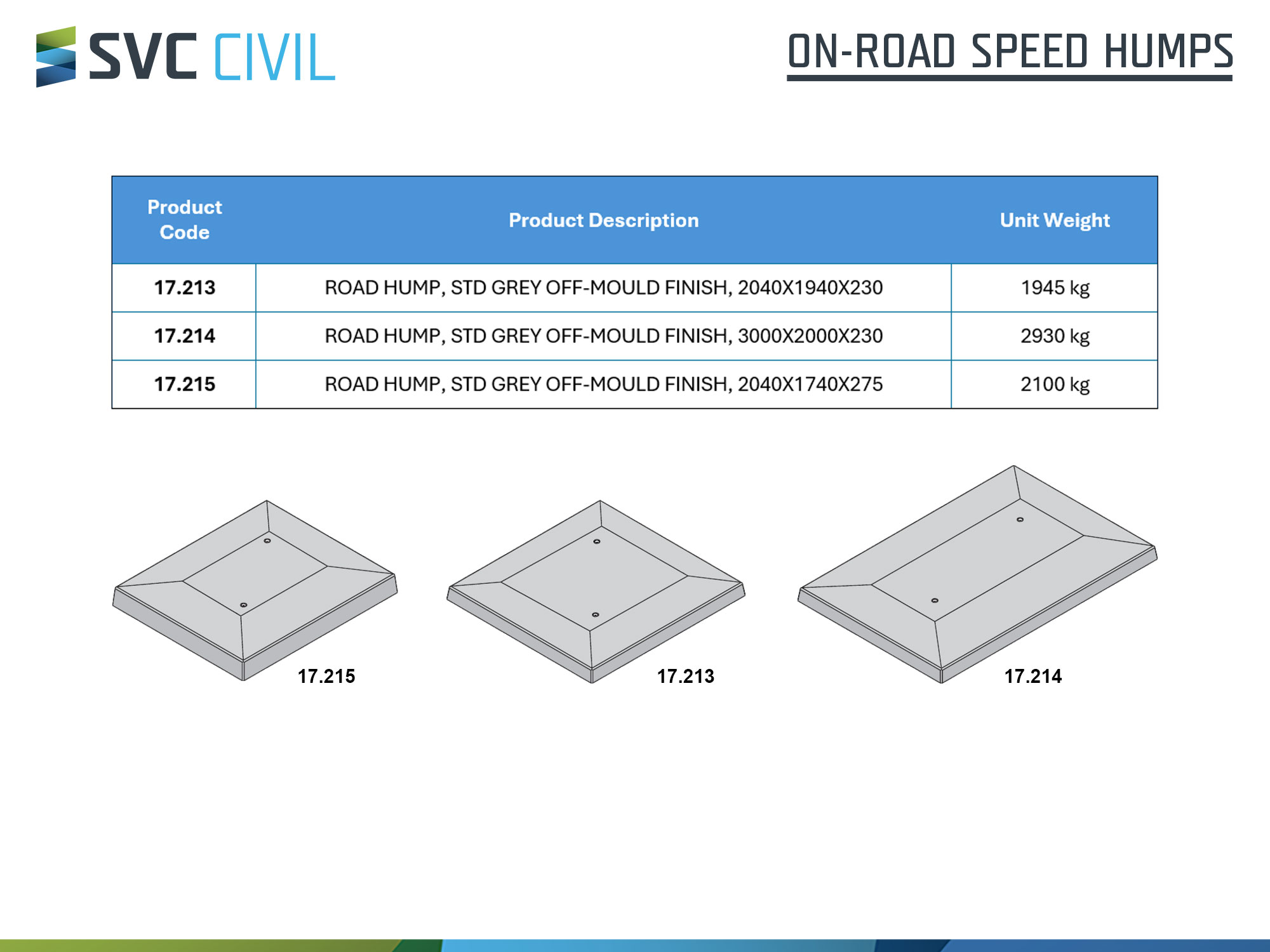

Manufactured from high-strength precast concrete, SVC’s speed humps offer superior longevity and performance compared to asphalt or rubber alternatives, which can deform and degrade over time due to the stresses of regular vehicular impact. With each concrete speed hump weighing close to 2T in mass, their heavy-duty, robust construction resists degradation and movement upon impact, instead offering a consistent, robust on-road solution that safely slows down traffic.