Spiked Kerbs by SVC Civil offer an easy-install solution for traffic separation and control, preventing vehicles from crossing a designated line. Once installed, spiked kerbs effectively block vehicles from accidentally mounting a pedestrian walkway, overshooting a parking bay, bumping into walls or entering restricted areas.

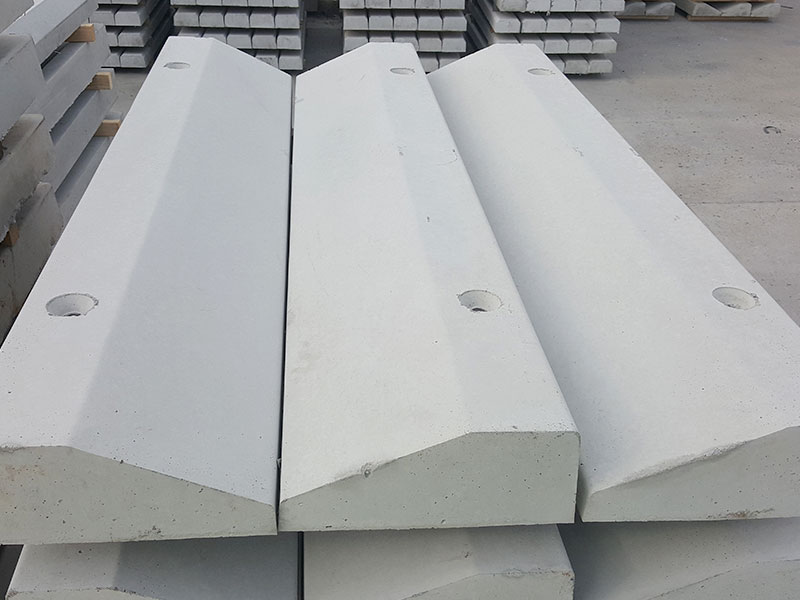

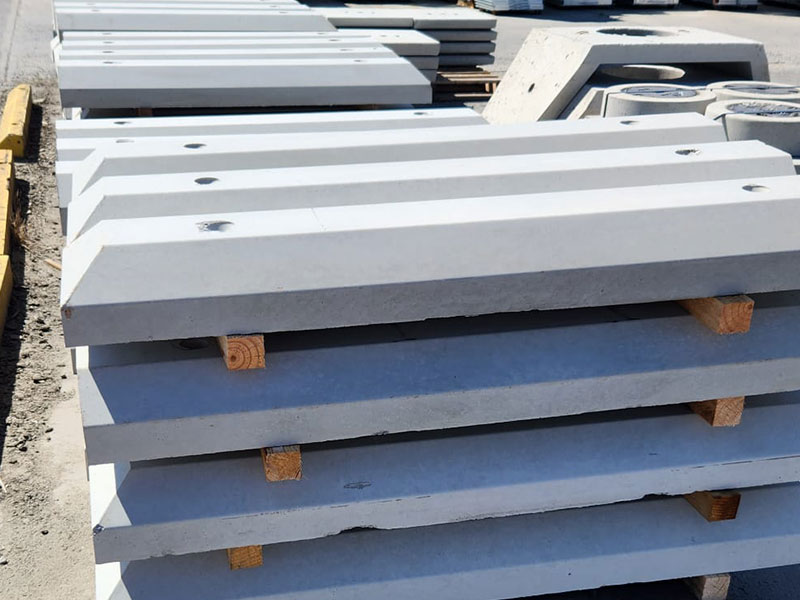

Manufactured from high-strength, reinforced concrete and available in two kerbing profiles, SVC’s precast concrete spiked kerbs offer a durable, vandal-proof alternative to rubber or plastic kerbing products. They are a valuable component for any car park construction, traffic management or refurbishment project.