Living and working by the sea is an ideal scenario for many, and coastal areas are becoming increasingly populated with new residences and businesses. To prepare the land for urban inhabitation, seawalls and other structures are introduced as protective measures against flooding and coastal erosion. However, this typically causes a decrease in marine biodiversity, due to the replacement of geological shoreline habitats with flat, inorganic surfaces.

Melbourne-based design studio Reef Design Lab and the Sydney Institute of Marine Science (SIMS) are addressing this problem via the Living Seawalls initiative. Living Seawalls is an ongoing research project that aims to reintroduce marine biodiversity to existing coastal infrastructure, developing a blueprint that can be used to inform future designs.

Melanie Bishop, Associate Professor at Macquarie University and a member of the Living Seawalls leadership team, advises:

“Designing seawalls that incorporate features of natural habitats can enhance their ecological value. Our research is assessing how advances in 3D printing and materials science can be best utilised to improve biodiversity on seawalls, as well as other coastal infrastructure.”

Backed by hefty support from various project sponsors, the Living Seawalls team has successfully developed a series of modular concrete panels. Designed to be retrofitted onto existing seawalls, the modules mimic the geometric features found in natural rocky shores, making them more conducive to supporting the intertidal ecosystem than the flat seawalls to which they are attached.

Alex Goad, industrial designer and founder of Reef Design Lab, is no stranger to working within the marine environment. His collaboration with SIMS commenced in 2015, when a researcher first reached out to Goad after discovering his previous work in developing an artificial reef structure. From this connection, early Living Seawall prototypes were created utilising Goad’s expertise in 3D printing and industrial design.

Armed with input from ecologists at SIMS and inspiration from natural marine habitats such as rock pools, crevices and pits, Goad designed four unique seawall modules. Each design was intended to be as different from the others as possible, to assess which geometries would be most suited for the colonisation of different species. The consistent modularity of the tiles allowed for all four types to be installed together, with the tiling layout customisable for individual site environments.

Concrete has traditionally been the material of choice for marine infrastructure, dating as far back as ancient Rome. For the Living Seawalls project team, the selection of concrete for the seawall modules was an obvious choice due to the material’s durability, cost-effectiveness and ability to withstand the volatile intertidal environment.

Goad comments,

“The intertidal environment is especially corrosive. It’s the worst environment you could be putting anything in, except for maybe a volcano? Part of our testing will look at how the material degrades, as it’s constantly getting smashed by waves, experiencing cyclical forces and going from wet to dry all the time.

We want to build something that will last as long as possible, and concrete is one of the best materials for that.”

3D-printed moulds for the seawall modules were produced at the RDL studio. The next step was to find a manufacturer who could create the modules and maintain the fine detail in the geometric forms and surface textures. Goad approached SVC Products, a precast concrete manufacturer whose main production facility happened to be just minutes from the RDL studio.

With extensive prior experience in pre-fabrication of custom concrete products, the team at SVC were happy to participate. Though SVC’s typical manufacturing outputs are heavy, large-format products for civil and landscape construction, the challenge of producing hundreds of highly intricate, 580mm-diameter seawall modules was too enticing to pass up.

Dyan Harper, Special Projects Manager at SVC, remarks,

“Our team is exceptionally skilled at producing bespoke items out of concrete, and we appreciate client requests that challenge us to find innovative ways to achieve seemingly complex shapes. We are thrilled at the opportunity to work with Reef Design Lab to create these modules that not only look aesthetically amazing, but also possess long-term ecological benefits.”

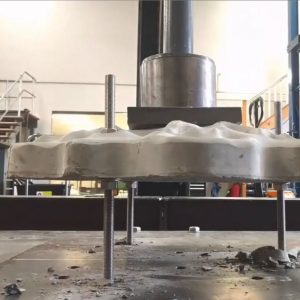

A special concrete mix was used to cast the seawall modules, allowing the intricacies of each design to be retained while meeting strength requirements. Prior to implementation, the modules had to undergo various tests to ensure they could survive in the intertidal environment. Successful test completion saw the seawall panels able to withstand up to 2 tonnes of pressure while still maintaining structural integrity.

To date, Living Seawalls have been installed at two locations in Sydney Harbour, with algal and invertebrate growth on the modules occurring within a matter of weeks. SIMS researchers will continue to gather various types of data from the Living Seawalls project over the next two years, in hopes of determining best practices for future seawall construction.

“The research team is monitoring the efficacy of the installations in enhancing the biodiversity of seawalls, as well as key ecological functions such as water filtration, carbon uptake and nutrient cycling. The results will help to ascertain the scale of installations needed to provide tangible ecological benefits, and also those specific designs most suited to specific ecological goals such as improvement of water quality or enhancement of fisheries productivity.”

Melanie Bishop, Sydney Institute of Marine Science

The benefit of increased biodiversity on seawalls is threefold. Not only does it support a thriving marine ecosystem, but the presence of habitat-forming creatures such as oysters and other molluscs also creates a protective buffer for the seawall itself. Active organisms in the intertidal environment essentially clean the waterways by feeding on pollutants and particles in the water, activating a natural filtration system with positive ramifications that extend to recreational fishers and beachgoers.

Urbanisation of the shoreline will only increase as population growth continues to surge. Through its findings, the Living Seawalls initiative aims to define a methodology for future seawall design, and will investigate further ways of implementing ‘green’ seawalls on a larger scale in coastal cities across Australia and the world. Within the next few years, the project team intends to develop commercially viable products that will allow businesses to easily adopt ecologically-friendly designs when constructing new coastal infrastructure.

We thank Melanie Bishop and Alex Goad for their contributions to this article.

The Living Seawalls initiative is sponsored by Harding Miller Foundation, Kirby Foundation, the NSW Environmental Trust and Volvo Australia.

Alex Goad is a designer and sculptor with a passion for underwater construction. While many of his peers studying Industrial Design chose to pursue automotive design for their honours projects, Goad worked on the development of a modular artificial reef structure (MARS) to support coral farming and reef restoration. Reef Design Lab was formed out of Goad’s desire to work with marine biologists, allowing him to use actual research to refine his designs until they achieved real-world feasibility. The award-winning MARS system has since been installed at Summer Island in the Maldives, operating in conjunction with the local coral farm.

The Sydney Institute of Marine Science is a world-leading research institute at the forefront of marine research and innovation. Formed in 2005 as a partnership between the top universities in Sydney, SIMS is represented by a diverse group of over 100 scientists and students dedicated to sharing their environmental understanding and expertise. The institute has initiated various programs such as the World Harbour Project, which led to the creation of a global network of collaborating scientists operating in major urban harbours of the world.